Most Fleet Managers face difficulties reducing vehicle and equipment-based expenses, especially operational costs. Operating costs increase if you don’t know which factors cause the surge.

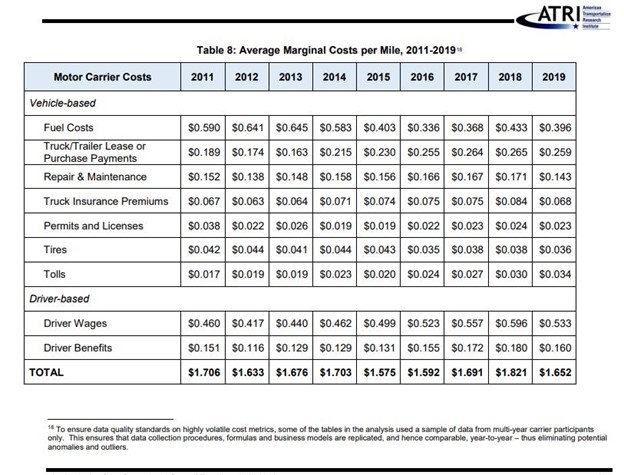

In 2019, the Avg. of marginal costs per mile incurred by motor carriers dropped 9.3% to $1.65 as the below table shows from ATRI;

Source: trucknews.com

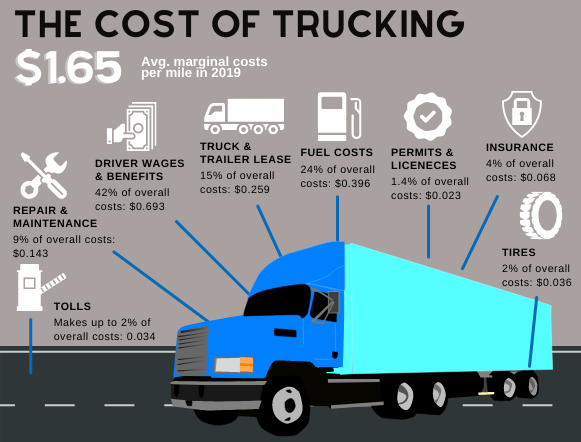

The following image shows a quick overview on what the greatest operating costs for Fleets are by percentage.

Your operating costs may be like this, or you may not know the exact cost per item if you lack proper reporting tools.

Thanks to new technology and Artificial Intelligence, knowing the actual operational costs and predictive maintenance costs is a lot easier and much faster for Fleet Managers to make decisions when it comes to reducing Fleet operational costs.

Fleet Management platforms today provide Fleet Managers with full control of maintenance, safety, dispatch, and management of drivers’ workload.

By monitoring real-time data and driver behavior provided by a Fleet Management platform, you can pinpoint rising costs when they emerge and plan to reduce the operating costs.

5 ways to reduce Fleet Operational costs

Here are 5 ways to reduce Fleet operational costs with a Fleet Management system.

1. Optimize routes

Inefficient routes hugely affect your operation costs by consuming more fuel, reducing your Fleet’s productivity, and it also leads to delivery or service delays.

However, GPS Fleet Tracking provides you with optimal routes which help prolong vehicle life span and eliminating unnecessary driving time. Fuel costs are one of the largest factors in Fleet expenses. By providing an easy search of locations, you can reduce fuel utilization and fuel waste. The route optimization given by GPS Fleet Tracking helps on-time or quick delivery which can also improve customer service.

2. Assess Fleet costs

Understanding how much your operational costs per mile is critical to analyze which factor is causing more expense. You might get the number from profit/loss statements by comparing it with prior statements to see the overall expense trend. However, this method is not accurate and can be fluctuate depending on the needs if a given operation.

To examine your actual operating costs on a weekly or monthly basis, you need Fleet Management software to plan, control, and manage costs of operating costs. With the management tool, you can record all works, parts, and costs of each unit so the cost per mile of each unit can be calculated easily and accurately.

3. Educate drivers

Unsafe driving habits can have a huge impact on Fleet productivity and cost-efficiency. Reckless driving causes preventable accidents and unnecessary repairs. If your company is larger, managing all vehicles and drivers becomes much more complicated.

With Fleet Management software, it is simple to monitor your driver’s behavior in real time. Fleet Managers can also establish a baseline score across all drivers in your Fleet based on their driving habits. It is an easy and intuitive way to provide coaching to your drivers by analyzing and highlighting top critical events that contributed to their score. As the result, your operational costs will be optimized by improving engine idling, speeding, and other undesirable behaviors.

4. Reduce idling

Idling time attributes to one of the biggest unknown operating costs with unnecessary fuel consumed. According to Natural Resources Canada, idling Wastes Fuel and Money. For the average vehicle with a 3-litre engine, every 10 minutes of idling costs 300 milliliters (over 1 cup) in wasted fuel – and one half of a liter (over 2 cups) if your vehicle has a 5-litre engine. Unnecessary idling wastes fuel – and wasted fuel is wasted money. Average annual idling at 30 minutes per day, would cost a Fleet Owner $8,694 per year for a Fleet of 30 vehicles. That more than pays for the cost of implementing a Fleet Management solution, without considering any other ROI metrics.

5. Analyze Fleet lifecycle

If you know the best timing of maintenance, repairs, inspections, car washes, etc, you can prolong the lifespan of your vehicles without spending unnecessary costs. In addition, keeping your vehicles longer than necessary could cost you more than leasing new ones.

With a Fleet Management system, Fleet Managers can analyze and make key decisions on the timing of vehicles replacements by monitoring and Tracking data of Fleet maintenance, fuel usage, utility, vehicle wear, breakdown, accidents incurred by bad driving behavior.

We can help you

Astreon is one of the leading providers of solutions in the AVL/GPS Tracking industry. We are consistently introducing new wireless platforms, shaping the future, and changing the way people do business. Astreon provides you with the services and applications that you need to be more productive and responsive to today’s increasing industry demands.

We provide an accurate and affordable means of Tracking your workforce. With compact mobile devices, combined with the extensive coverage of today’s wireless networks, we enable users to track and monitor virtually anything; not just where cellular service is available, but anywhere you can see the sky. The result is improved security, productivity, and a superior customer experience. Today we offer GPS Fleet Management services to businesses throughout North America. We offer location and telematics-based solutions vehicles or all shapes and sizes, equipment, high-value assets, and valuable cargo.

Our customers rely on our services daily as business process management tools and benefit from multiple add-on tools and applications such as Compliant ELD, Maintenance Management, Driver Coaching, Video Management Dashboard, KPI Management Dashboards, Logistics & Dispatch tools, and many more. Connect with us today to find out more about how Astreon can benefit your business.

Contact us today!

Tel: +1 (888) 647-4730

Email: sales@astreon.com